Steel Body PDC Bit 3-S1655FC1

Steel-body

Steel is metallurgically opposite of matrix. It is capable of withstanding high impact loads, but is relatively soft and, without protective features, would quickly fail by abrasion and erosion. Quality steels are essentially homogeneous with structural limits that rarely surprise their users.

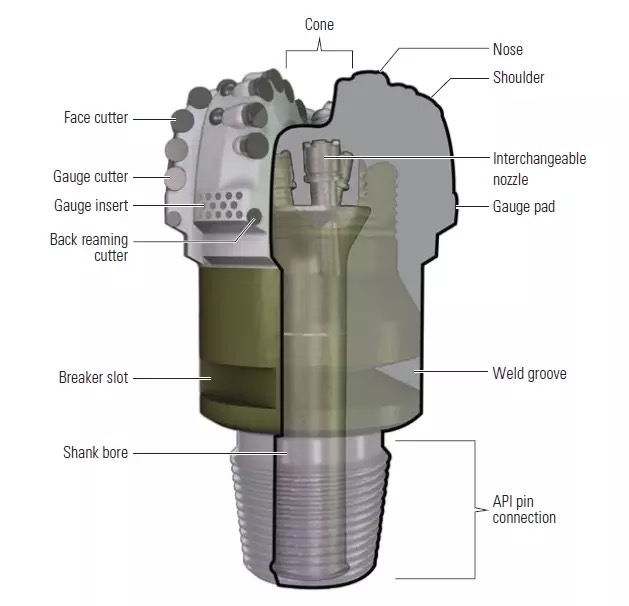

Product Features

Steel PDC bit with five blades of parabola crown profile and with middle cutter density With interchan geable screw nozzles.

Asymmetrical blades arrangement and special load-balanced cutter arrangement design improve bit stability and therefore higher ROP Non-plane interfaced diamond /carbide cutters absorb effectively high stress and minimize cutter fracturing and wearing.

Both tilted and cauterized nozzles design improves bit cleaning and prevents bit balling,thus to improve ROP Can be used on rotary or down hole motor drilling.

The PDC bit is suitable for soft to medium hard formation. High HIS is recommended.

1、Double rows spiral five blades design significantly increases wear resistance and stability of the bit.

2 、Inserted with 13mm X 13mm cutter,,enhances drilling footage capability of the bit.

3、The surface of the blade is welded by wear-resistant hardfacing material, improves wear resistance and erosion resistance of the bit.

Features:

1、Deep blade and long parabolic configuration and deepen the maximum waterway. Optimize hydraulic design of the bit, significantly increases chip removal efficiency.

2、Optimize the cutting structure, places high quality cutters in low density, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances the drilling stability.

Advantages of Products:

1.Short parabolic crown profile, medium cutter density.

2. Interchangeable screw nozzle.

3. Structured diamond/carbide interface. Cutter delays the onset of Fracturing and cutter wear.

4. Undercut shank maximizes junk slot area for better bit cleaning. Hign filt nozzles for improved hydraulics and Rop. 5. Can be used on rotary or down hole motor.

6. Surfable for soft to medium formation.

Application: Suitable for soft to medium hard formation with high compressive strength and abrasiveness,such as limestone, mudstone and sandstone,etc.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

8-1/2” |

5 |

16.05mm |

7 |

2’’~3.5’’ |

4-1/2’’API REG |

60~250 |

10~100 |

25~36 |

FAQ

1. About lead time?

Answer: We always have regular inventory of models, and we ship them after payment, which is our advantage. Bulk production depends on the quantity of the order. In China, it usually takes three to five days to get to Tianjin port or Beijing airport. Small or urgent orders can be airlifted to the customer upon receipt of approval. According to the diatance from China to the ports, it takes about 30days frpm China to Europe, and about 25 days to the Western United States by sea.

2. About payment terms?

Answer: We accept all regular payment terms, including letters of credit, T/T, etc.

3. About Transport?

Answer: Sea or air freight. We are close to Beijing Airport and Tianjin seaport (Xingang). It takes only one day from our factory to Beijing or Tianjin. It is a fast and very economical inland toll.

4. What is the package?

Answer: We use high quality export wooden boxes or you can customize.

5. How do we guarantee our quality?

Answer: We select the advanced production technology and equipment, strictly control the whole production process,and we inspected the finished drill bits,we can also make several design changes according to the customer’s feedback, and finally ensure the customer’s excellent drilling effect. Each of the drill bits sold will be quality-tracked, detailing the usage feedback to improve our deficiencies.

6. How to get an accurate quote?

Answer: A simple way is sending us photos. Besides above, if possible please provide more information as below: drilling depth in vertical well drilling, drilling length in HDD, hardness of rocks, capacity of drill rigs, application (oil/gas well drilling, or water well drilling, or HDD, or foundation). The more information provided, the more exact quotation will be offered.