Matrix pdc bit M1661FC 8.1-2

Polycrystalline diamond compact (PDC) bits deliver premium performance and durability for a wide range of standard drilling applications. These matrix- and steel-bodied bits incorporate the latest cutter technology, computational fluid dynamics (CFD), enhanced hydraulics, and various structure geometries to maximize ROP.

Matrix-body bit

Matrix-body PDC bits are commonly preferred over steel-body bits for environments in which body erosion is likely to cause a bit to fail. For diamond-impregnated bits, only matrix-body construction can be used.

Steel-body bits

The strength and ductility of steel give steel-bit bodies high resistance to impact loading. Steel bodies are considerably stronger than matrix bodies.A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

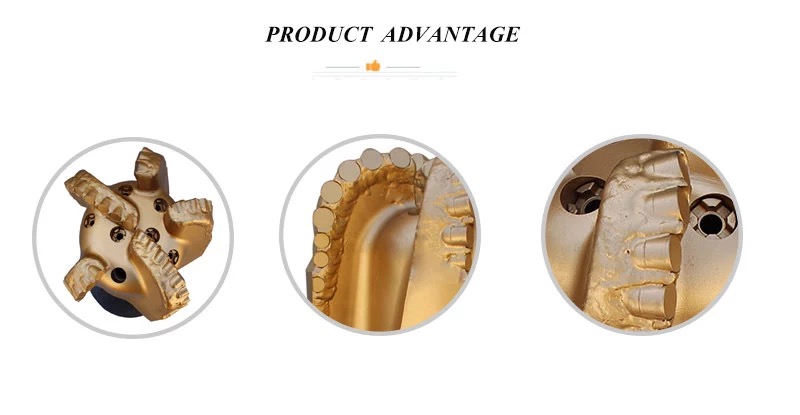

1、Double rows spiral six blades design, significantly increases wear resistance and stability of the bit.

2、Extended gauge ensures the bit is maintained for a long period of time,increases the steady resistance to pressure of the bit.

Features:

1、Deep blade and medium parabolic configuration design, ensures optimal bottom hole flow pattern and anti-balling.

2、Optimize the cutting structure and place high quality cutters at different points, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances the drilling stability.

4、Manufactured with high quality tungsten carbide matrix powder, ensures the erosion resistance of the bit.

Application: Suitable for medium hard formation with high compressive strength and abrasiveness, such as limestone, hard gypsum, dolomite and sandstone, etc.

1,Suit for drilling medium to medium-hard formations.

2,Evolute asymmetrical blade cutter design and balanced bit load so that bit whirl is prevented.

3,Composite gage protection and low torque design improve rate of penetration.

4,CFD hydraulic balance design results in better bit cleaning and cutting removal .

5,Combined utilization of high performance PDC compacts significantly prolongs bit life

6,Higher nozzle counts and/or fixed ports to best serve cleaning,cooling and cuttings evacuation

requirements with available hydraulic flows.Allows for higher flow rates with minimal increase in pump pressure.

Feature:Diamonds are impregnated in the matrix behind the PDC cutters

Benefit:Increased footage drilled in abrasive applications.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

8-1/2” |

6 |

16mm |

6 |

2’’~3.5’’ |

4-1/2’’API REG |

60~250 |

10~100 |

25~36 |