Low MOQ for Tricone Drilling - Steel Body PDC Bit S1655FGA5 – Ruishi

Low MOQ for Tricone Drilling - Steel Body PDC Bit S1655FGA5 – Ruishi Detail:

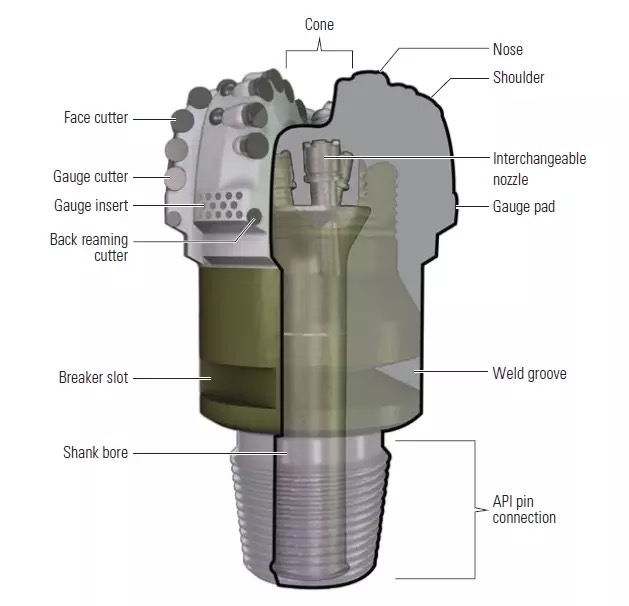

1、Double rows five blades design, lessens bit torque and improves steerability in directional drilling.

2、Unique gauge with high quality PDC cutters, helps several-fold increasing wear resistance and stability of the bit.

3、The surface of the blade is welded by wear-resistant hardfacing material, improves wear resistance and erosion resistance of the bit.

Polycrystalline diamond compact (PDC) bits deliver premium performance and durability for a wide range of standard drilling applications. These matrix- and steel-bodied bits incorporate the latest cutter technology, computational fluid dynamics (CFD), enhanced hydraulics, and various structure geometries to maximize ROP.

Matrix-body bit

Matrix-body PDC bits are commonly preferred over steel-body bits for environments in which body erosion is likely to cause a bit to fail. For diamond-impregnated bits, only matrix-body construction can be used.

Steel-body bits

The strength and ductility of steel give steel-bit bodies high resistance to impact loading. Steel bodies are considerably stronger than matrix bodies.A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

Features:

1、Deep blade and long parabolic configuration design,ensures optimal bottom hole flow pattern and anti-balling.

2、Optimize the cutting structure and places high quality cutters at different points, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances the drilling stability.

Application: Suitable for medium hard formation with high compressive strength and abrasiveness, such as limestone, hard gypsum, dolomite and sandstone, etc.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

8-1/2” |

5 |

16.05mm |

6 |

2’’~3.5’’ |

4-1/2’’API REG |

60~250 |

10~100 |

25~36 |

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Low MOQ for Tricone Drilling - Steel Body PDC Bit S1655FGA5 – Ruishi , The product will supply to all over the world, such as: New York, Florida, Doha, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.